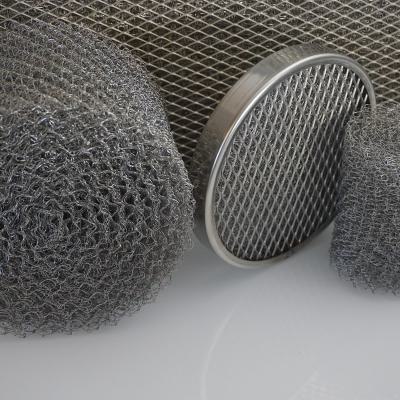

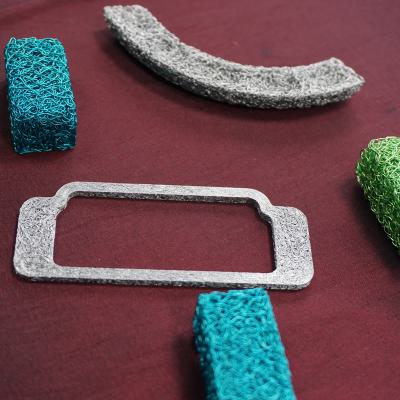

Quality knitted wire meshes.

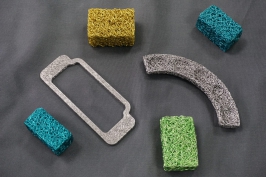

As an innovative manufacturer of high quality knitted wire meshes we have for many years been a dependable partner in the automobile manufacturer and supplier industries as well as for renown companies in the process and environmental engineering industries. Working closely with our customers we design individual solutions for their filtration, positioning and insulation applications. We moreover view the continual development of new and improved knitted wire meshes as an especially important challenge. Our in-house tool shop provides us the ability to produce functional prototypes very quickly and efficiently. DHD knitted wire meshes are produced with endless wire by an Omega forming machine. The primary advantage over other knittted wire is the three dimensional movement ability of the knitted meshes.

Our services

Wire meshes

As an innovative manufacturer of high quality wire meshes, we have been a reliable partner to the automotive and supplier industry as well as leading companies in process and environmental technology for many years.

Environmental

Environmental protection is a matter of course today. DHD filter elements help to keep air and water clean.

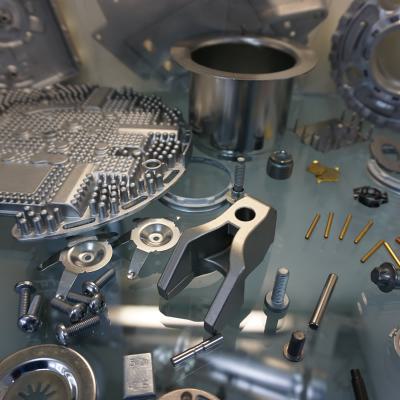

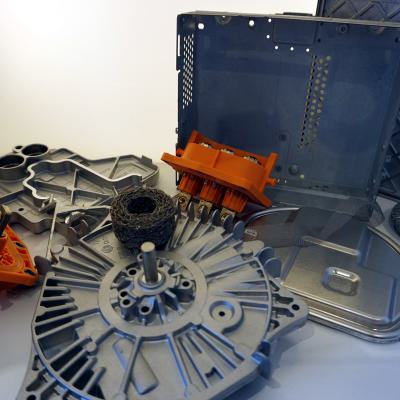

Parts cleaning

For years, we have been professionally cleaning turning, milling, stamping, stamping, die-casting and wire bending parts for the automotive industry and mechanical engineering. The used full vacuum system with perchlorethylene cleans economically and effectively.

Filter cells and metal filters

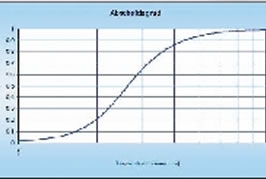

DHD metal filter cells are individually made to measure. The pressure loss in wire mesh filters is between 10 and 70 Pa with a filter depth of 8 - 100 mm.

Lab Service - Dirt Analysis

Accredited laboratory according to DIN ISO 17025. Residual soil analysis according to VDA 19 or ISO 16232.

Surface treatment

Tempering profiles up to 1,200 ° C can be driven in the shuttle kiln. The monitoring of the tempering process is recorded by means of temperature / time recording 100%.

Parts cleaning

Parts cleaning - Wage cleaning procedure For many years we clean professionally trick, Milling, Punching, Pressing, pressure downpour, and wire flexible…

Wire meshes

Wire meshes for automotive engineering, process engineering and environmental technology As an innovative manufacturer of high quality knitted wire meshes…

Environmental

Environmental Demister and DHD drop separators Today environment is a self-evident fact. DHD Filter elements help in the cleaning of…

Lab Service - Dirt Analysis

Lab Service - Dirt Analysis - Analysis filtration: In up to 3 membranes catching washbin parts are cleaned by means of splashing,…